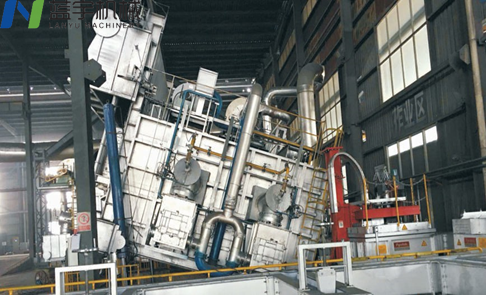

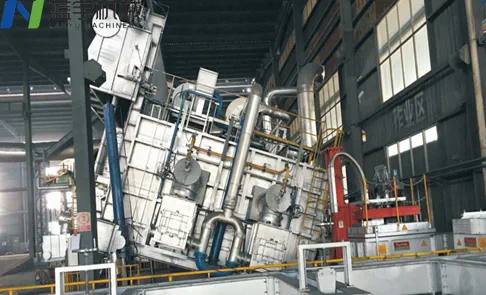

Tilting Smelting Furnace / Holding furnace

- Smelting furnace , Holding furnace

- April 26, 2025

Table of Contents

Main Applications >

The inclined pouring melting furnace and insulation furnace are primarily used in enterprises producing high-end aluminum alloy rod materials and aluminum sheet/band products. By precisely controlling the casting process of molten aluminum, it is possible to effectively improve product quality and production efficiency while reducing safety risks and preventing explosion accidents. This equipment is particularly suitable for enterprises engaged in recycled aluminum processing and scrap aluminum remelting.

Technical Specifications

Structure of Melting Furnace

- Section steel furnace body

- Insulation material

- Fire-resistant lining materials

- Furnace roof design

- Lifting door

- Hydraulic lifting mechanism

- Combustion system

Optional Structures of Melting Furnace

Furnace Body Type

- Double channel steel furnace body

- I-beam furnace body

Furnace Roof Design

- Hinged brick casting roof

- Arched casting roof

Molten Pool Structure

- Brick-built molten pool structure

- Semi-casting structure

- Full-casting structure

Heating Methods and Energy Sources

- Natural gas

- Heavy oil

Design Types

According to the actual site conditions and raw material process requirements of customers, the following types can be selected:

- Single furnace (primary furnace) operation

- Mother-child furnace (high-low furnace, also known as secondary furnace) operation

By flexibly selecting structures and heating methods, the equipment meets the production process needs of different enterprises, optimizing production efficiency and reducing energy consumption.

Main Models >

15T, 20T, 25T, 30T, 35T, 40T, 45T